Humans as "superspreaders" of plant-damaging viruses

- maltenevermann

- Dec 17, 2025

- 9 min read

Hygiene measures against ToBRFV on clothing and footwear

The tomato brown rugose fruit virus (ToBRFV) has been a concern for international fruit vegetable growers for almost a decade now. Since its first appearance in Israel and Jordan, the virus has been detected in over 30 countries and is causing considerable economic damage worldwide.

This reduces the harvest yield by 30-70%; additionally the market value of the fruit can be reduced if the tomatoes show symptoms, mostly changes in color and shape. The severity of the symptoms depends in particular on the variety of the host plant; some new tomato varieties are tolerant to infection with ToBRFV and therefore show no or only very mild symptoms.

However, it is not only tomatoes that are affected, but also other plant species from the Amaranthaceae and Solanaceae families. These include the cultivated plant paprika, ornamental plants such as petunias and ornamental tobacco, and weeds that are widespread in our region, such as foxtail, goosefoot, and black nightshade.

Within an infested plant population, in the open field, greenhouse, or even in a polytunnel, ToBRFV is spread very effectively mechanically through contact between an infected plant or a contaminated object (e.g., hands, shoes, tools, tables, crates, and bumblebees) and a healthy plant. The high stability of ToBRFV enables it to survive in soil, water, and on inanimate surfaces for months or even years if no suitable host plant is available.

Since January 1, 2025, ToBRFV has been categorized in the EU as a Union regulated non-quarantine pest (URNP); a similar regulation has been in force in Switzerland since July 1, 2025. This means that the obligation to report or control the virus has been lifted, but the pathogen is still subject to official plant health measures. These measures aim to prevent ToBRFV infestation in the production and marketing of young plants and seeds of tomatoes and peppers.

In tomato cultivation, in addition to seeds and young plants, humans are considered the main driving force behind the internal spread of this highly stable virus.

Humans as carriers

In order to understand how ToBRFV spreads from infected plants to distant areas of the farm, extensive research was conducted at the Department of Phytomedicine at Humboldt University in Berlin. This research included clothing and gloves, as well as the surfaces of various solid and movable objects in the production area and the living environment of the workers.

The outer clothing of the workers was already heavily contaminated with ToBRFV after one day of work – regardless of the visual degree of soiling of the respective T-shirt (Fig. 2). Seven employees of a company with a ToBRFV outbreak were provided with white cotton T-shirts at the start of work, which were collected at the end of the working day, packed separately, and sent for testing. Sixteen standardized 3x3 cm fabric samples were tested for infectious ToBRFV, taking into account the sleeves, hip and abdominal regions, back, neck, and chest areas. Unused T-shirts served as negative controls. The T-shirts worn by each of the seven employees were successfully used to infect test plants. In two of the seven worn T-shirts, all 16 fabric samples cut out were ToBRFV-positive, and in five other T-shirts, 15 of the 16 samples were contaminated with ToBRFV. The subsamples without ToBRFV came from random locations: the front and back of the T-shirt, as well as the sleeves and upper body, and did not correlate with the degree of contamination. As expected, the T-shirt that was not worn by an employee in the greenhouse was completely free of ToBRFV.

With the start of intensive cultivation and harvesting work, the infection rate in crops rises significantly—often to the point of complete infestation. Targeted cleaning and disinfection measures have therefore been developed to help vegetable farms effectively control ToBRFV infections.

Viruses on clothing – an underestimated danger

During daily cultivation work, work clothes such as shirts, pants, and T-shirts come into frequent contact with plants. The virus contained in plant sap can easily transfer to textiles, where it can remain and later be reintroduced into the crop.

ToBRFV is only completely inactivated at temperatures around 90°C. A wash cycle at these temperatures not only requires a lot of energy, but is also unsuitable for polyester and nylon fabrics or corresponding blended fabrics, especially with regard to preserving color and fiber structure. However, lower washing temperatures carry the risk of infectious viruses entering the environment via wastewater.

Sanitization of work clothes

In order to answer practical questions about how to handle used and sometimes very dirty work clothes, a comparative study was conducted on the efficiency of various household detergents, special cleaning agents and disinfectants (Table 1) for the safe cleaning of ToBRFV-contaminated clothing. For this purpose, cotton textiles were contaminated with ToBRFV-infected plant sap in a standardized manner, allowed to dry, and then treated with the various cleaning solutions at the concentrations recommended by the manufacturer.

Categories | Product | Manufacturer | Concentration (%) |

|---|---|---|---|

Household detergent | Spee Aktiv Gel | Henkel AG | 0,25 |

Household detergent | Vanish Oxi Action Gel | RB Hygiene Home Deutschland GmbH | 2,5 |

Special cleaning agent | MENNO HORTISEPTCLEAN Plus | MENNO CHEMIE-VERTRIEB GmbH | 2 |

Special cleaning agent | FADEX H+ | MENNO CHEMIE-VERTRIEB GmbH | 2 |

Disinfectant | MENNO Florades | MENNO CHEMIE-VERTRIEB GmbH | 4 |

Table 1: Household detergents, special cleaning agents, and disinfectants used to clean ToBRFV-contaminated cotton fabric, including product name, manufacturer, and application concentration.

The results of the study were clear:

The products tested on behalf of the household laundry detergent category, Spee Aktiv Gel and Vanish Oxi Action, did not sufficiently remove ToBRFV — neither from the fabric nor from the washing solution.

In contrast, MENNO HORTISEPTCLEAN Plus and FADEX H+, which were tested in the category of special agricultural cleaners, and the disinfectant MENNO Florades achieved almost complete virus inactivation.

Contaminated washing solutions could also be safely disinfected retrospectively by adding MENNO Florades.

Recommended hygiene routine for horticultural businesses when handling work clothing potentially contaminated with stable plant viruses

Pre-cleaning: After the workday, soak worn work clothes in a cleaning solution of MENNO HORTISEPTCLEAN Plus, FADEX H+, or MENNO Florades at room temperature for at least 10 minutes (e.g., in a wash tub).

Machine wash: Pre-clean work clothes and wash them in a conventional washing machine; a household washing machine is sufficient.

Follow-up treatment: The used solution can be reused several times or treated with MENNO Florades (4%) for surface disinfection.

Shoe soles – an often overlooked transmission route

In addition to clothing, shoes/boots very often provide stable plant viruses with a means of transport to a new host plant, thus contributing to the spread of the respective pathogen within the farm.

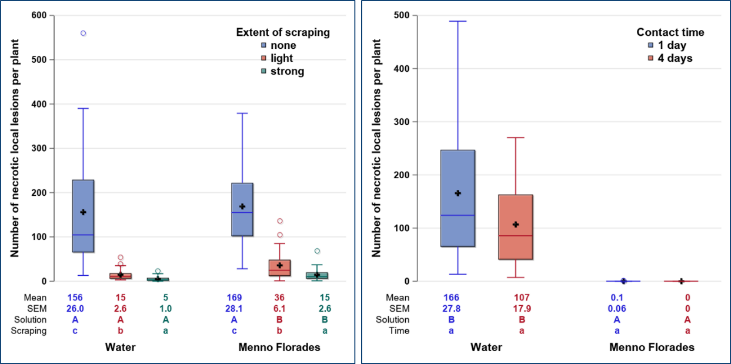

Such contamination can be counteracted with disinfectant mats, especially at entrances and exits. Tests with disinfection mats filled with MENNO Florades (4%) showed that mechanical cleaning—through intensive scrubbing or brushing—is necessary before the disinfectant can take effect (Figs. 3, 4). ToBRFV accumulated in mats that were filled with water alone and remained infectious for several days – impressive evidence of the need for effective disinfectant solutions.

ProfilGate clean-off zone with MENNO Florades

Vehicles and machines are indispensable in modern vegetable cultivation—but they are also potential carriers of plant pathogens. Virus particles can attach themselves to tires and rollers in particular and spread throughout the farm.

A recent study by Humboldt University in Berlin (Department of Phytomedicine) shows that the combination of a ProfilGate clean-off zone and MENNO Florades is capable of reducing the highly stable tobamovirus ToBRFV on vehicle tires and casters by 90–99% within a few seconds (Fig. 5).

While the transmission of pathogens via tools has been well researched and disinfection measures have been implemented in operational processes, tire and roller decontamination has long been considered a weak point in many hygiene concepts. The use of appropriate mats often proved unsuitable in practice, as the weight of the vehicles/equipment or sharp-edged wheels, for example, severely limited their functionality and service life. ProfilGate systems, on the other hand, consist of very stable grid modules with pre-tensioned brush strips that actively clean the tire treads when driven over (Fig. 6). The modules are filled with MENNO Florades (4%), which immediately wets the cleaned treads with disinfectant. This mechanically removes dirt and viruses and then chemically inactivates them – fully automatically and without any loss of time.

In the practical test, tires with standard treads made of polyurethane, polyamide, and rubber were taken into account. The treads were standardized with ToBRFV-infected plant debris, tomatoes, or ToBRFV-contaminated substrate and defined pure ToBRFV suspensions with various ToBRFV concentrations. After drying, they were driven over a ProfilGate zone, and the wipe samples taken after the passage were subjected to a biological test for infectious ToBRFV. The investigations showed:

Even with high ToBRFV contamination, the system achieved a reduction of 94.4% compared to the control (Fig. 7).

The material of the tread had no influence on the cleaning success.

The length of the acidification zone must be adapted to the operating conditions, but should be at least 5 m.

The disinfectant solution in the grid module itself remained virus-free, and accumulation could be ruled out.

Practical tip

ProfilGate in combination with MENNO Florades ensures fast, reliable, and safe decontamination of vehicle tires/rollers during operation. Installation is particularly suitable for entrances/exits to sensitive production areas. This effectively minimizes or even prevents the introduction and spread of pathogens.

Integrate the handling of work clothing and the use of disinfection mats into the company hygiene plan in the same way as washing and cleaning hands.

Provide immersion tanks for work clothes

Replace shoe disinfection mats regularly

Clean and disinfect gloves and tools

Hairnets can prove to be a useful preventive measure, especially for long hair, to stop the spread of stable plant viruses such as ToBRFV.

Hygiene as a component of an insurance concept

Prevention is a fundamental component of any insurance policy, with the aim of averting avoidable damage. In horticulture, too, especially in integrated pest management, preventive measures are an indispensable tool for preventing losses in yield and quality. At the same time, the question arises: What costs can be expected for a hygiene concept as a preventive measure to prevent the introduction and spread of harmful organisms? And more importantly, is it worth it?

To answer these questions, a few assumptions must first be made for the calculation. Modern greenhouses (GWH) are estimated to have a surface area of approximately 40,000 m² per hectare of floor space. Effective hygiene concepts require the entire surface to be cleaned and disinfected. For each m² of surface area, 0.2 l of working solution is applied for both the cleaning and disinfection steps. This results in a requirement of 8000 l of cleaning solution and 8000 l of disinfectant solution per hectare of GWH floor space. Prices were requested from the manufacturer for the cost calculation. Based on these, the quantity calculation results in prices per square meter of: approx. 10 cents for cleaning, approx. 55 cents for disinfection, and approx. 6 cents for personal hygiene (personal communication from Dr. Jens Ehlers, MENNO Chemie Vertriebs GmbH).

This means that a comprehensive hygiene concept can be established in your business for as little as approximately 70 cents per square meter per year. In most cases, less than 1% of turnover needs to be spent on such preventive hygiene measures as an insurance component in fruit vegetable cultivation. In return, effective protection is offered against pathogens, some of which cause damage significantly exceeding 30%. Each producer must decide for themselves whether it is worthwhile.

Carmen Büttner1 und Martina Bandte2 und Ute Vogler3

1, 2 Humboldt-Universität zu Berlin, ADTI, Fachgebiet Phytomedizin, Berlin, Deutschland

3 Julius Kühn-Institut, Bundesforschungszentrum für Kulturpflanzen, Institut für Pflanzenschutz im Gartenbau und Urbanen Grün, Braunschweig, Deutschland